Deitu iezaguzu

+86-19858305627

E-posta iezaguzu

sales@maple-machinery.com

Materialak manipulatzeko ekipoen inbertsioa galdatzeko osagaiak Fabrikatzaileak

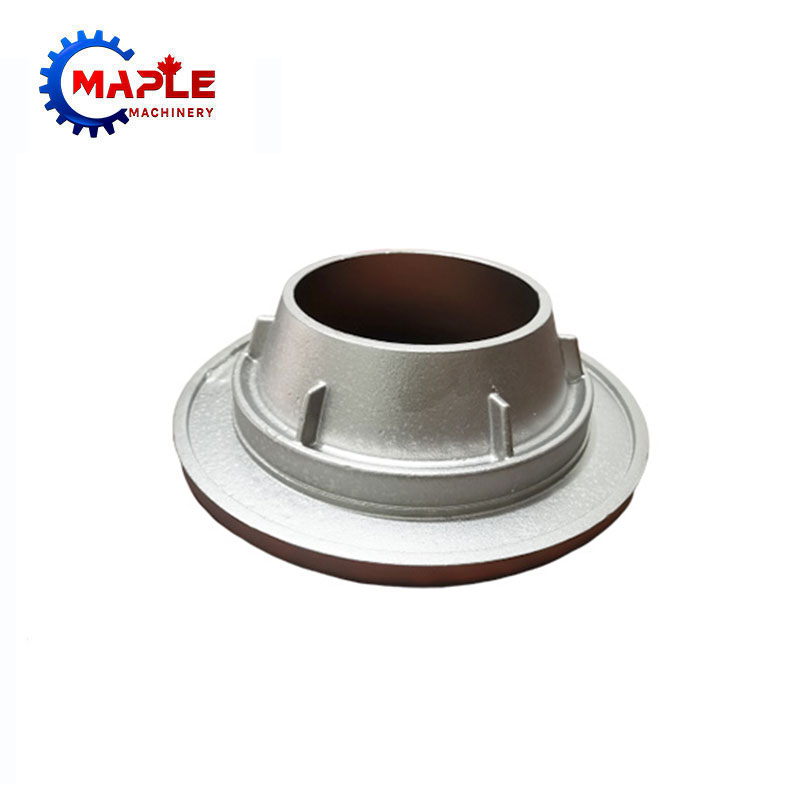

Gure fabrikak harea galdaketa, trokel itxia, forja irekia, etab. Muturreko diseinua, kalitatezko lehengaiak, errendimendu handia eta prezio lehiakorra dira bezero bakoitzak nahi duena, eta hori ere eskaintzen dizugu. Kalitate handiko, arrazoizko prezioa eta zerbitzu ezin hobea hartzen ditugu.

Produktu beroak

Ingeniaritza Zibileko altzairuzko trokel itxiak forjatzeko piezak

20 urte baino gehiagoz, Maple Machinery Co., Ltd., Ningbo-n (Txina) kokatua, trokel itxien forjatzaileen fabrikatzaile profesionala da, bezeroei kalitate handiko Ingeniaritza Zibileko altzairuzko forja-piezak eskaintzeko espezializatua. Horrez gain, produktu bukatuetarako balio erantsiko beste zerbitzu batzuk ere eman ditzakegu. Hori dela eta, pieza forjatuak eta mekanizatuak behar badituzu, jar zaitez gurekin harremanetan!Sistema hidraulikoa Altzairu herdoilgaitzezko galdaketako piezak

Maple makineriaren sistema hidraulikoa altzairu herdoilgaitzezko galdaketarako piezak fidagarritasunagatik ezaguna da, baina fidagarritasunean oinarritutako gure lan-etika ez da hor gelditzen. Gure lanaren alderdi guztietan agertzen dela ziurtatu nahi dugu, gure produktuetatik hasi eta bezeroen arretarako eta lankidetzarekin. Harro gaude epe luzerako bezeroekiko harremanak sortzeaz.Industria astuneko burdina harikorra galdaketarako piezak

Ningbo-n (Txina) kokatua, portutik hurbil, bere ekoizpen planta du, baita bezeroei kalitatearekin eta azken teknologiarekin lan egiteko irtenbideak eskaintzera dedikatzen den ingeniaritza-talde bat ere. Mundu osoari balio du. Gure espezializazioari, gure makineria modernoari eta kalitate handiko produkzio-teknologiari esker, ekoizpen-faseak kalitate handiko industria astuneko burdinazko galdaketa-piezen kantitate egokia eskaintzen du.Off Highway Industry Altzairu herdoilgaitzezko forja-piezak

Maple makinak bezeroei Off Highway Industry Altzairu Herdoilgaitzezko Forja Pieza sorta zabala eskaintzen die. Gure konpetentzia nagusia Off Highway Industriarako bezeroen sistema espezifikoen soluzioen garapena da, eskakizun zorrotzenak asetzeko. Bolumena, zehaztasuna, segurtasuna eta fidagarritasunaz gain, gure bezeroek gero eta teknologia handiagoa eta eraginkortasun ekonomikoa bilatzen dute.Balbula Iron Sand Casting zatia

Maple makinak 15 urte baino gehiago daramatza Valve Iron Sand Casting Piezas fabrikatzen eta Ningbo-n (Txina) egoitza duen metal fabrikatzailea da. Helburua metalak eta pieza metalikoak fabrikatzeko formazio tekniko eta metalurgikoa duen enpresa bat sortzea zen. Harro gaude azken 15 urteotan gure bezero globalak modu eraginkorrean zerbitzatzeko gai izan garelako. Orduz geroztik, gure esperientzia eta espezializazio teknikoa aprobetxatu dugu Estatu Batuetan, Kanadan eta Ipar Amerikan dauden bezero askoren eskakizunak betetzeko.Nekazaritza-makineria Altzairu herdoilgaitzezko forja-piezak

Maple-k 15 urte baino gehiagoko esperientzia du nekazaritzako makineriarako forjatutako produktuak fabrikatzen. Nekazaritza-makineria Altzairu herdoilgaitzezko forja-piezakNekazaritzako doitasuneko forja-produktuak ekoitzi ditzakegu produktu automatikoen prozesamenduaren bidez. Bezeroen behar desberdinak asetzea. Gure produktuen errendimendua bermatzen dugu. Bestalde, bezeroaren eta merkatuaren ikuspegiaren esparruan, arreta handiz planifikatzen ari gara hornikuntza-katearen osotasuna mantentzea eta bezeroen beharrei egoera onenean erantzutea.

Bidali kontsulta

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy