Deitu iezaguzu

+86-19858305627

E-posta iezaguzu

sales@maple-machinery.com

Balbula burdinazko harea galdatutako piezak Fabrikatzaileak

Gure fabrikak harea galdaketa, trokel itxia, forja irekia, etab. Muturreko diseinua, kalitatezko lehengaiak, errendimendu handia eta prezio lehiakorra dira bezero bakoitzak nahi duena, eta hori ere eskaintzen dizugu. Kalitate handiko, arrazoizko prezioa eta zerbitzu ezin hobea hartzen ditugu.

Produktu beroak

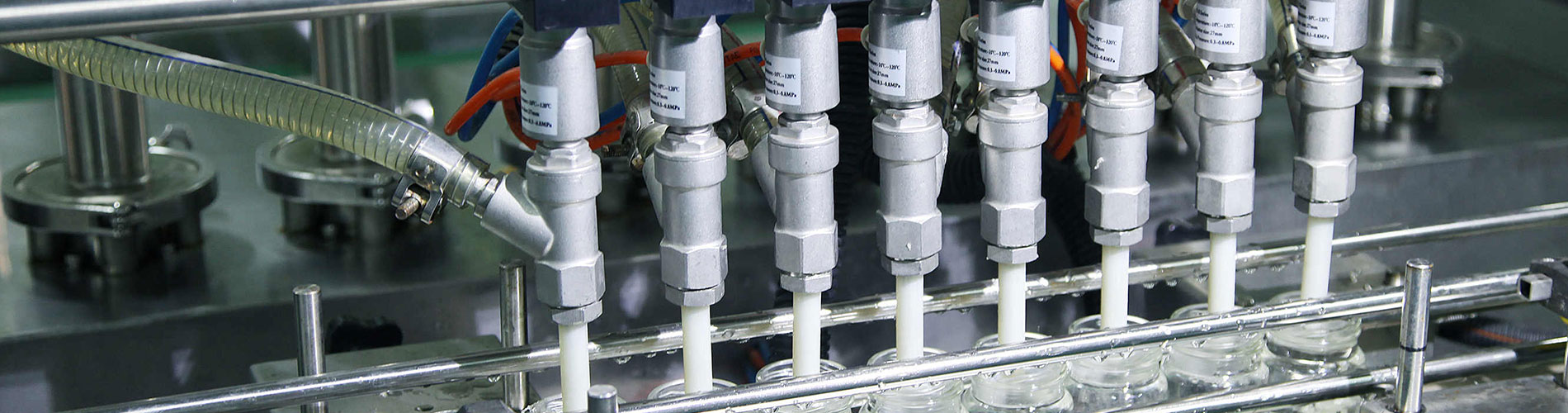

Elikagaiak Prozesatzeko Makina Altzairu Galdaketa Pieza

Maple makineriaren kalitatea kudeatzeko sistema ziurtatuak bermatzen du antolaketa eta plangintza prozesuak gure eguneroko negozioan optimizatuta daudela. Ondorioz, gure barne-prozesuak eta produktuak etengabe hobetzeko gai gara. Elikagaien Prozesatzeko Makina Altzairu Galdaketa Pieza guztiak estandarrak direla ziurtatzeko. Maple makineria Elikagaien Prozesatzeko Makinen industrian bezeroak zerbitzatzen ari da. Lorpen onak ere lortu dira.Nekazaritzako Makineria Altzairuzko Trokel Itxiak Forjatzeko Piezak

MapleMachinery-k ia 20 urteko esperientzia du nekazaritzako ekipoen industrian. Aleazioak forjatu eta prozesatzen ditugu, karbono altzairua, altzairu aleatua, altzairu herdoilgaitza eta aluminioa barne. Gure forjaren azken erabilerak nekazaritza-makinen zatietatik hasi eta laboreak biltzeko ekipoen osagai nagusietaraino daude. Nekazaritza-ekipoen kostua murrizteko, astigarrak forja-prozesuetako batzuk automatizatu ditu, nekazaritza-makineria altzairuzko trokel itxiak propietate mekaniko koherenteekin fabrikatzeko eta ekoizpen-zikloa asko laburtzeko.Elikagaiak Prozesatzeko Makina Burdina Harikorra Galdaketa Pieza

Sortu zenetik, produktibitate-ahalmenaren arloan konpromisoa hartu dugu, gero eta handiagoa den merkatuaren eskaerari erantzuteko, etengabe hobetzen dugu gure Elikagaien Prozesatzeko Makina Burdina Harikorra Galdaketa Pieza eta kalitatea. Produktu guztien ekoizpena makina-piezetatik hasi eta pieza ertainetaraino, beren gaitasunak hobetzeko. Bezeroen beharrak asetzea.Birziklapen Industria Grey Burdin Galdaketa Pieza

Astigarrak makineria Sand Casting prozesuak Birziklapen Industria Grey Iron Casting Piezas ekoizten ditu. Hondar moldeak egurrez edo metalezko ereduez eginak dira. Ale fineko harea erretxina aglutinatzailearekin nahastu zen abiadura handiko nahasgailu batean eta ereduzko kaxetan isurtzen zen. Minutu batzuk igaro ondoren, harea-itsasgarriaren nahasketa gogortu egin zen eta moldea eredutik kendu zen. Prozesu bera erabiltzen da galdaketaren barruko egitura egiteko erabiltzen diren nukleoetarako.Balbula Altzairu Galdutako Argizaria Galdaketa Piezak

Maple makineriaren espezializazio tekniko sofistikatuak eta esperientziak inspiratzen eta motibatzen gaituzte zehaztasun-galdaketaren eremuan sartzera, Valve Steel Galdutako Argizari Galdaketa-Piezak perfekzioan fabrikatzen ditugun. Ingeniari metalurgiko eta mekaniko kualifikatu eta esperientziadun talde bat gara. Gure fabrika Ningbo-n dago, Txinan. Gure produktuak ezin hobeak izan daitezen, ekipo eta makina aurreratuenak instalatu ditugu. Gainera, gure laborategia sortu dugu, azken tresnez hornitua, akabera ultraleuna, dimentsio-zehaztasuna eta behar den gogortasuna bermatzeko eta metal portzentaje zehatzak zehazteko.Nekazaritzako Makineria Burdina Harea Galdaketa Piezak

Maple Machinery-k burdinurtu grisa eta burdinurtu harikorreko galdaketak ekoizten ditu zure zehaztapen espezifikoen arabera, kantitate txikietatik handietara, eta zerbitzuak eskaintzen ditu, hala nola tratamendu termikoa, prozesatzea, margotzea eta muntaia. Nekazaritza Makineria Burdina Harea Galdaketa Nekazaritza ekipamendurako piezak bezeroen zehaztapen zehatzen arabera. Maple makinak egindako burdinazko galdaketaren indarra, zehaztasuna, pisua eta itxura nekazaritza-makinen merkatuak hobesten ditu. Nekazaritza-makinen industriako gure bezeroek nekazaritza-makineria fabrikatzen dute. , nekazaritza-tresneria eta beste nekazaritza-makineria batzuk.

Bidali kontsulta

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy