Deitu iezaguzu

+86-19858305627

E-posta iezaguzu

sales@maple-machinery.com

Gas eta petrolio findegirako altzairuzko osagaiak Fabrikatzaileak

Gure fabrikak harea galdaketa, trokel itxia, forja irekia, etab. Muturreko diseinua, kalitatezko lehengaiak, errendimendu handia eta prezio lehiakorra dira bezero bakoitzak nahi duena, eta hori ere eskaintzen dizugu. Kalitate handiko, arrazoizko prezioa eta zerbitzu ezin hobea hartzen ditugu.

Produktu beroak

Nekazaritza-makineria Altzairu herdoilgaitzezko forja-piezak

Maple-k 15 urte baino gehiagoko esperientzia du nekazaritzako makineriarako forjatutako produktuak fabrikatzen. Nekazaritza-makineria Altzairu herdoilgaitzezko forja-piezakNekazaritzako doitasuneko forja-produktuak ekoitzi ditzakegu produktu automatikoen prozesamenduaren bidez. Bezeroen behar desberdinak asetzea. Gure produktuen errendimendua bermatzen dugu. Bestalde, bezeroaren eta merkatuaren ikuspegiaren esparruan, arreta handiz planifikatzen ari gara hornikuntza-katearen osotasuna mantentzea eta bezeroen beharrei egoera onenean erantzutea.Elikagaiak Prozesatzeko Makina Altzairu Galdaketa Pieza

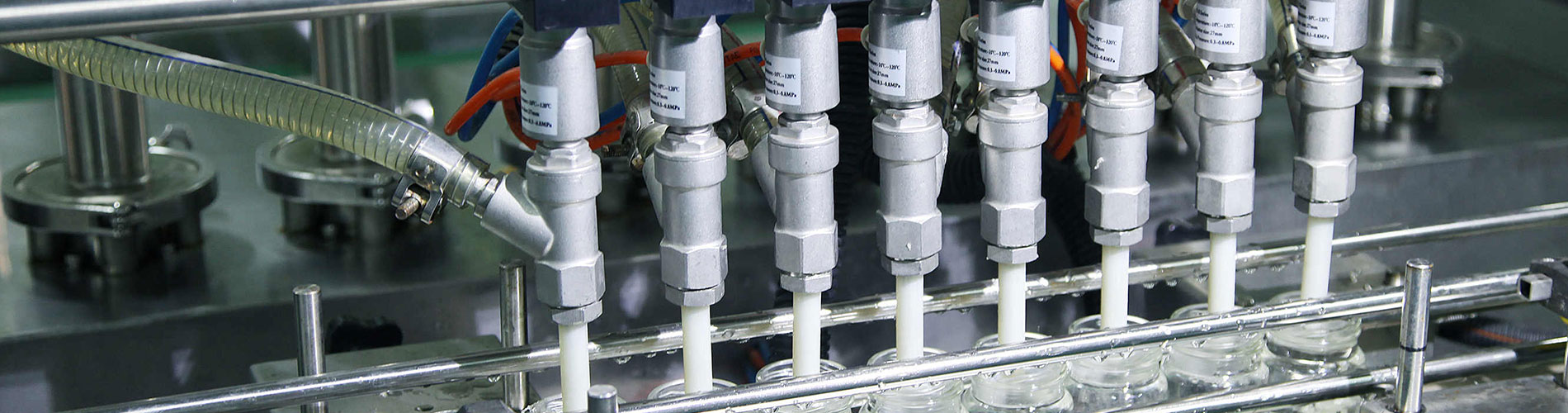

Maple makineriaren kalitatea kudeatzeko sistema ziurtatuak bermatzen du antolaketa eta plangintza prozesuak gure eguneroko negozioan optimizatuta daudela. Ondorioz, gure barne-prozesuak eta produktuak etengabe hobetzeko gai gara. Elikagaien Prozesatzeko Makina Altzairu Galdaketa Pieza guztiak estandarrak direla ziurtatzeko. Maple makineria Elikagaien Prozesatzeko Makinen industrian bezeroak zerbitzatzen ari da. Lorpen onak ere lortu dira.Itsas altzairuzko forjarako piezak

Metal Forjaketa mota nagusi gisa, Steel Forging altzairua konformatzeko teknologia bat da, tokiko konpresio indarra erabiltzen duena. Forjatzeek aldaketa nabarmenak izan dituzte, prozesu eraginkorragoak, azkarragoak eta iraunkorragoak izateko. Gaur egun, itsas altzairuzko forja-piezak, normalean, forja-prentsa edo mailu tresna elektriko, hidrauliko edo aire konprimituarekin egiten dira. Forjatze beroan pieza urtze-tenperaturaren %75 ingurura berotzea dakar.Industria astuneko altzairuzko forjarako piezak

Maple makineria azkar hazten ari den forja-produktuen hornitzailea da Txinan, gaur egungo forja-produktuen erronkei erantzutera bideratuta. Lorpen handia izan da bere sorreratik eta Industria Astunerako altzairu-kalifikazio ezberdinen forja-hornitzaile nagusietako bat da. Maple makineria bezero entzutetsuek eta proba-agentziek aitortzen dute bere kalitatezko industria astuneko altzairuzko forja-piezengatik. Gure konpainiak teknologia aurreratuenera bideratu du beti forja-produktu hobeak eskaintzeko urtez urte.Ingeniaritza Zibileko Burdin Harea Galdaketako piezak

Konpainia sortu zenetik, Maple makineria Iron Sand Casting Parts lehen egunetik kalitate handiko eta burdin galdaketa konplexuak ekoizten espezializatu da industria ugarirentzat. Gure bezeroei aluminiozko osagaietarako soluzio osoak eskaintzen dizkiegu. Gure erakundean, galdaketa konplexuen ekoizpenarekin lotutako azpiprozesu bakoitza egiten dugu. Honek Ingeniaritza Zibileko Burdina Galdaketa Piezen barneko soluzio osoa bermatzen du, non bezeroek beren Burdina Galdaketa Piezen hornitzaileengandik itxaroteko eskubidea duten kalitate eta fidagarritasunaz baliatzen diren.Industria Astuneko Altzairu Inbertsio Galdaketa Piezak

Maple makineriak historia luzea du Heavy Industry Steel Investment Casting Parts-en, eta historiatik eta kudeaketa-metodo modernoetatik pilatutako indar profesionala osagarri eta integrazio bikaina lortzeko. Orain etengabeko berrikuntza eta garapenaren bidez, teknologiak jauzi handia eman du.

Bidali kontsulta

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy