Deitu iezaguzu

+86-19858305627

E-posta iezaguzu

sales@maple-machinery.com

Itsas aplikaziorako altzairu herdoilgaitzezko galdaketa Fabrikatzaileak

Gure fabrikak harea galdaketa, trokel itxia, forja irekia, etab. Muturreko diseinua, kalitatezko lehengaiak, errendimendu handia eta prezio lehiakorra dira bezero bakoitzak nahi duena, eta hori ere eskaintzen dizugu. Kalitate handiko, arrazoizko prezioa eta zerbitzu ezin hobea hartzen ditugu.

Produktu beroak

Balbula altzairuzko harea galdatzeko piezak

Balbula altzairuzko harea galdaketako piezak fabrikatzen esperientzia handia duen fabrikatzailea gara eta kalitate handiko moldeak galdaketa-prozesuan osagai kritikoenak direla uste dugu. Lanaldi osoko 2 eredu-egile ditugu 60 urte baino gehiagoko industria-esperientziarekin eta harreman bikainak dituzten Ipar Amerikako Valve konpainia aurreratuenetako batzuekin. Ez dago proiekturik konplexuegia Maple makineriarentzat. Higatutako/zaharkitutako piezaren alderantzizko ingeniaritza eginez, 2D zirriborroetatik ereduak sortuz edo 3D eredu berrien formatuetatik lan eginez, zure kontzeptuak eta diseinuak hartu eta casting bihurtzeko gaitasuna dugu.Industria astuneko burdina grisa galdaketako piezak

Maple Makineria Heavy Industry Grey Burdin Galdaketa Piezen fabrikatzailea da, galdaketa mota ezberdinen ekoizpenean espezializatua. Kide-enpresa bakoitzak bere ezagutza eta ekoizpen-teknologia espezifikoak ditu. Burdinola guztiek beren jarduera independenteak dituzte. Konpainiak neurrira egindako Iron Sand Casting Piezas egiten ditu mundu mailako bezeroentzatMeatzaritza Industria Altzairu Galdaketa Piezak

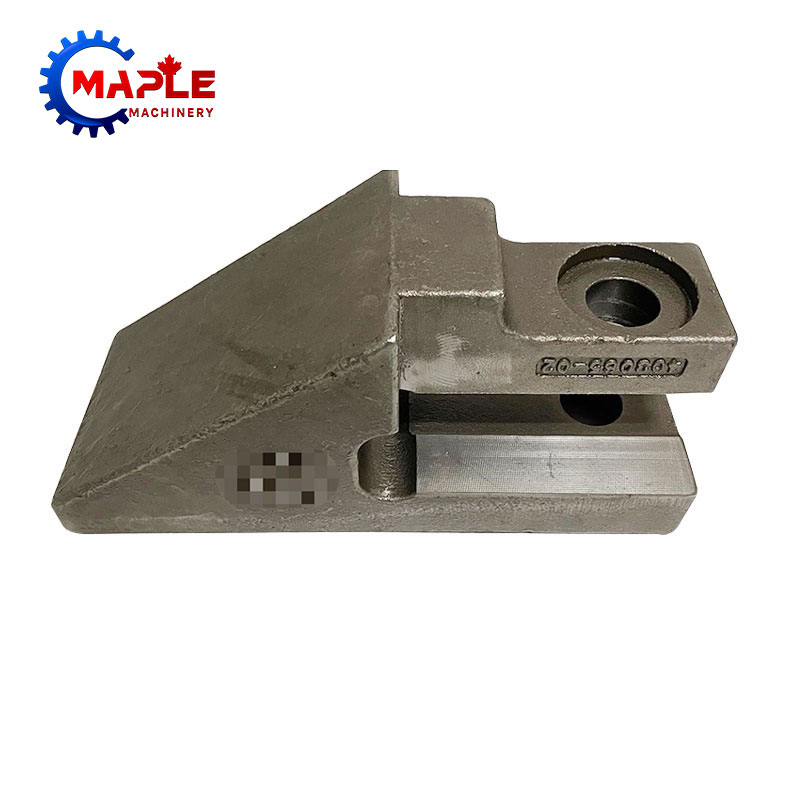

Maple Makineria ona da Meatze-Industria Altzairu Galdaketa-Piezak, aleaziozko altzairuzko zulaketa-puntak edo beste egitura-pieza batzuk fabrikatzeko. Maple Makineriak Australia, Kanada eta Europan meatze-ekipamenduen fabrikatzailearekin lan egiten du, beti hornitzen ditu meatze-ekipo edo makinarako altzairu galdaketa estandar handiko piezak.Birziklapen Industria Altzairu Inbertsio Galdaketa Piezak

Maple makineria Ningbon dago, portutik hurbil dagoen hiri batean, eta hori oso onuragarria da gure garraio lanetarako. Gure produktuen trukeetarako lagungarria da. Birziklapen Industriaren Altzairuzko Inbertsio Galdaketa Piezen garapenak goranzko joera erakusten du munduan. astigarrak makineria birziklapen industria altzairuzko inbertsio galdaketa piezen etengabeko ikerketetan aritu da.Eraikuntzako makineria Altzairuzko galdaketako piezak

Maple makinerian kalitatea, segurtasuna eta zerbitzua dira gure lehiakortasun nagusia. Gure galdategiak ekipamendu mekaniko eta malgutasun aurreratuak ditu, eta horrek zure Eraikuntzako Makineria Altzairu Galdaketa Piezen behar guztiak ase ditzake eta bezero zorrotzen eskakizunak betetzen lagunduko dizu. Gure galdategiak segurtasuna, garbitasuna eta eraginkortasuna mantentzeko konpromisoa hartzen du. Urteetan zehar, Maple-k etengabe inbertitu du ekipamendu aurreratuenetan, industriaren abangoardian bihurtuz.Elikagaiak Prozesatzeko Makina Burdina Harikorra Galdaketa Pieza

Sortu zenetik, produktibitate-ahalmenaren arloan konpromisoa hartu dugu, gero eta handiagoa den merkatuaren eskaerari erantzuteko, etengabe hobetzen dugu gure Elikagaien Prozesatzeko Makina Burdina Harikorra Galdaketa Pieza eta kalitatea. Produktu guztien ekoizpena makina-piezetatik hasi eta pieza ertainetaraino, beren gaitasunak hobetzeko. Bezeroen beharrak asetzea.

Bidali kontsulta

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy