Deitu iezaguzu

+86-19858305627

E-posta iezaguzu

sales@maple-machinery.com

Birziklapen Industria Altzairu Galdaketa Piezak Fabrikatzaileak

Gure fabrikak harea galdaketa, trokel itxia, forja irekia, etab. Muturreko diseinua, kalitatezko lehengaiak, errendimendu handia eta prezio lehiakorra dira bezero bakoitzak nahi duena, eta hori ere eskaintzen dizugu. Kalitate handiko, arrazoizko prezioa eta zerbitzu ezin hobea hartzen ditugu.

Produktu beroak

Ingeniaritza Zibileko altzairu herdoilgaitzezko galdaketako piezak

Maple Machinery Ingeniaritza Zibileko Altzairu Herdoilgaitzezko Galdaketa Piezen hornitzaile bat da, eta oso doitasun handiko galdaketa konplexuak ekoizten ditu "argizari galdu" metodoa erabiliz. Ikuspegi orokor hori dela eta, gure ingeniariek askatasun handia dute produktuen diseinuan eta materialen aukeraketan. Horrek esan nahi du, zurekin kontsultatuta, zure nahi eta eskakizun zehatzak betetzen dituen casting onena ekoiz dezakegula. Maple makineria zure garapen-kidea da galdaketa arrakastatsurako, elkarren arteko kontsultaren bidez galdaketa-produktu onena ekoizteko helburuarekin.Off Highway Industry Burdina Harikorra Galdaketa Pieza

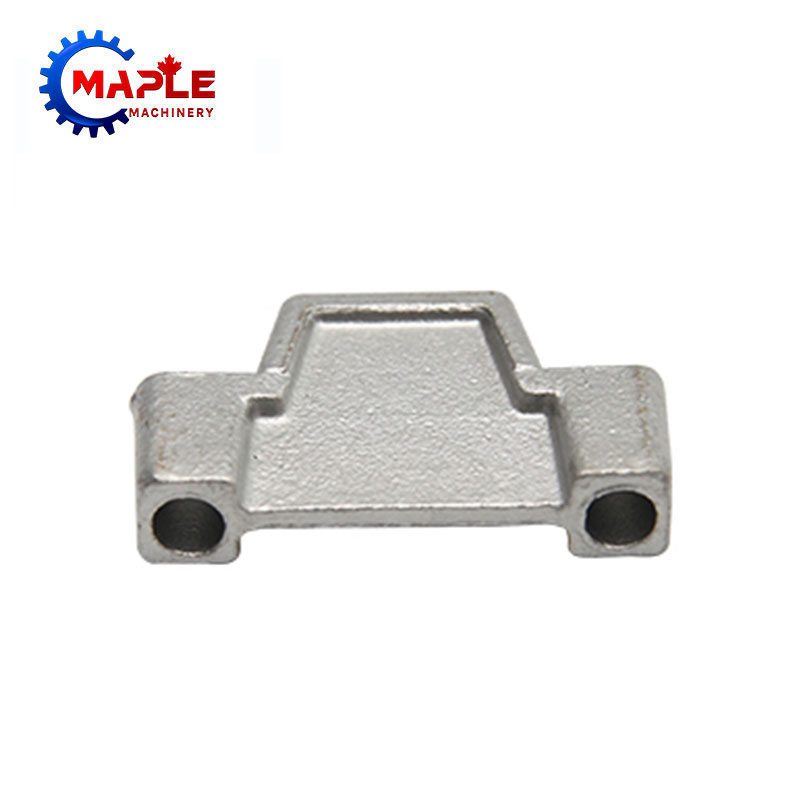

Maple makineria aukeratzen baduzu, bere lanbidearekin sutsua den Burdina Harikozko Galdaketa Piezen fabrikatzaile esperientziadun bat aukeratzen ari zara. Maple makineriak ia 20 urteko esperientzia du Off Highway Industriako Burdina Harikako Galdaketa Piezen garapenean eta ekoizpenean. Ductile Iron Casting-en urrats bakoitza pasioa eta kalitatea batera doazela jakitun da. Horrela, denek egunero garatzen dute burdina bezain indartsu talde gisa.Petrolioaren eta gasaren industria Altzairu herdoilgaitzezko forja-piezak

Maple makineria Ningbo-n dago, Txinan, Oil & Gas Industry Altzairu herdoilgaitzezko Forja-Piezen piezak ekoizteko, biltegiratzeko eta azpigarraioetarako, eta ondo kokatuta dago petrolio eta gas industriako hornitzaile nagusien beharrak asetzeko. Hainbat herrialdetako gure bezeroen hornitzaile ziurtatu eta homologatuekin konbinatuta, kostu baxuko herrialdeen hornikuntzaren onurak aprobetxatzeko aukera duzu eta jakin ezazu Maple-ren produktuei esker kalitatearen %100eko bermea dagoela.Birziklapen industria Altzairu herdoilgaitzezko galdaketa-piezak

Maple makineriak azken teknologia erabiltzen du gure inbertsio Galdaketa prozesuan kalitate handiko birziklapen industria altzairu herdoilgaitzezko galdaketa piezak modu eraginkorrean eta garaiz ekoizteko. Etengabe gabiltza teknologia berriak eta modu berritzaileak bilatzen gure Birziklapen Industriaren inbertsio-galdaketa-prozesua hobetzeko, gure eraginkortasuna, gure kalitatea eta gure epe laburtzeko.Off Highway Industria altzairu galdaketa piezak

MapleMachinery-k 20 urte baino gehiagoko ezagutza du erresistentzia handiko aleazioetan, manganeso-aleazioetan eta kastruioan. Gure esperientziadun ingeniaritza eta salmenta sailek beren espezializazioa erabiltzen dute Erresistentzia handiko Off Highway Industry Steel Casting Parts eskaintzeko, edozein trenbide bezeroren eskakizunak asetzeko. Gure piezak kalitate handiko lehengaiekin diseinatuta daude, trenbideko bezeroei trakzio-erresistentzia, korrosioarekiko erresistentzia eta errendimendu onena duten piezak eskaintzen dizkiegula ziurtatzeko. MapleMachinery-k pieza zaurgarrietarako aleazio pertsonalizatuak eta jabedunak ere garatu ditu, eta mikroegituraren eta beste propietate fisikoen eskakizun zehatzak betetzeko gaitasuna dugu.Petrolioaren eta gasaren industria altzairuzko forjarako piezak

Hamarkadetan zehar, Maple makineria petrolioaren eta gasaren industriaren hornitzaile nagusia izan da, kalitate handiko eta prezio lehiakorrak eskainiz. Petrolioaren eta Gasaren industrian, urpeko, gainazaleko eta haustura hidraulikoaren industrian dauden ingurumen-baldintza gogorrak direla eta, Maple-k kalitate goreneko materialak eta forja-zehaztasuna bermatzen ditu forja-baliabideen, gaitasunen eta esperientziaren bidez, eta petrolio- eta gas-industriako altzairuzko forja-pieza onenak ekoizten ditu. entrega-epe laburrena.

Bidali kontsulta

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy