Deitu iezaguzu

+86-19858305627

E-posta iezaguzu

sales@maple-machinery.com

Doizko burdina harizko galdaketa piezak Fabrikatzaileak

Gure fabrikak harea galdaketa, trokel itxia, forja irekia, etab. Muturreko diseinua, kalitatezko lehengaiak, errendimendu handia eta prezio lehiakorra dira bezero bakoitzak nahi duena, eta hori ere eskaintzen dizugu. Kalitate handiko, arrazoizko prezioa eta zerbitzu ezin hobea hartzen ditugu.

Produktu beroak

Industria Astuneko Altzairu Inbertsio Galdaketa Piezak

Maple makineriak historia luzea du Heavy Industry Steel Investment Casting Parts-en, eta historiatik eta kudeaketa-metodo modernoetatik pilatutako indar profesionala osagarri eta integrazio bikaina lortzeko. Orain etengabeko berrikuntza eta garapenaren bidez, teknologiak jauzi handia eman du.Ingeniaritza Zibileko altzairuzko argizaria galdatzeko piezak

Gure bezero estimatuen gogobetetasun handiena lortzeko, Ingeniaritza Zibileko Altzairu Galdutako Argizari Galdaketa Piezak eskaintzeko konpromisoa hartu dugu. Diseinu zehatza eta garapen indartsua, altzairua, materialak eta eguneroko beharrak dituzten enpresentzat, ekoizpen aukera egokia eskaintzeko. Produktu hauek azken teknologia berritzaileak erabiltzen dituzte eta industriako estandarren arabera ekoizten dira. Gainera, hauek alda daitezke bezeroaren baldintza zehatzak betetzeko.Sistema hidraulikoa Altzairu herdoilgaitzezko galdaketako piezak

Maple makineriaren sistema hidraulikoa altzairu herdoilgaitzezko galdaketarako piezak fidagarritasunagatik ezaguna da, baina fidagarritasunean oinarritutako gure lan-etika ez da hor gelditzen. Gure lanaren alderdi guztietan agertzen dela ziurtatu nahi dugu, gure produktuetatik hasi eta bezeroen arretarako eta lankidetzarekin. Harro gaude epe luzerako bezeroekiko harremanak sortzeaz.Nekazaritza-makineria Altzairu herdoilgaitzezko forja-piezak

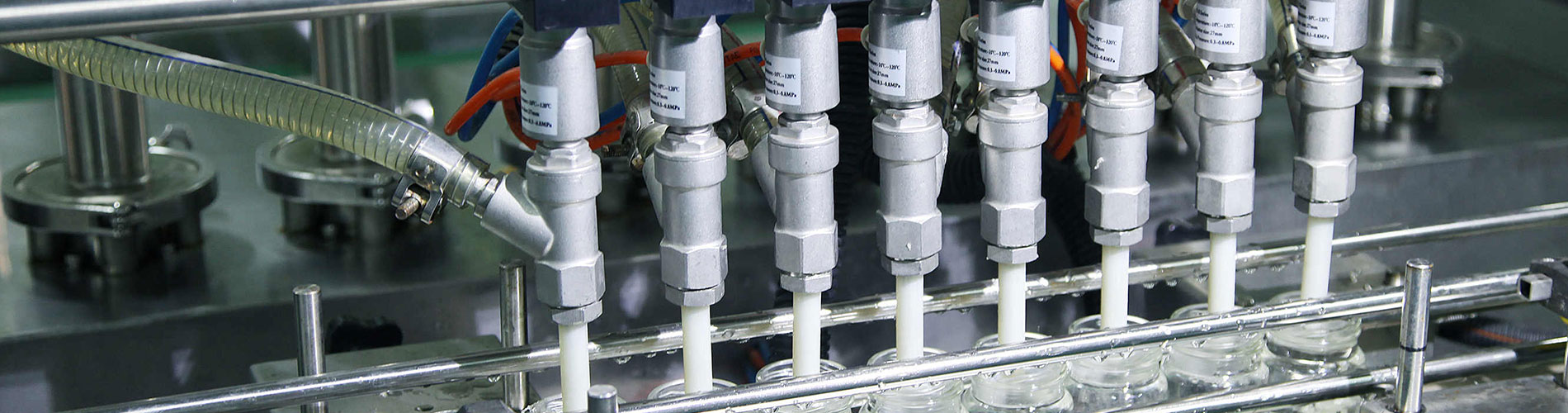

Maple-k 15 urte baino gehiagoko esperientzia du nekazaritzako makineriarako forjatutako produktuak fabrikatzen. Nekazaritza-makineria Altzairu herdoilgaitzezko forja-piezakNekazaritzako doitasuneko forja-produktuak ekoitzi ditzakegu produktu automatikoen prozesamenduaren bidez. Bezeroen behar desberdinak asetzea. Gure produktuen errendimendua bermatzen dugu. Bestalde, bezeroaren eta merkatuaren ikuspegiaren esparruan, arreta handiz planifikatzen ari gara hornikuntza-katearen osotasuna mantentzea eta bezeroen beharrei egoera onenean erantzutea.Elikagaien Prozesatzeko Makina Altzairu herdoilgaitzezko galdaketarako piezak

Elikagaien Prozesatzeko Makinarentzat, Maple makineria ingeniariek zure erakundearen luzapen gisa jokatzen dute doitasun galdaketaren garapenean. Gauzak "teknikoki hobeak, desberdinak, merkeagoak edo/eta sinpleagoak" izan daitezkeen kontuan hartuta, irtenbiderik onena prezio lehiakorrean lortzen dugu. Pozik gaude Galdaketa tekniken ezagutza zurekin partekatzeko Elikagaien Prozesatzeko Makina Altzairu Herdoilgaitzezko Galdaketa Pieza onenak diseinatzeko.Sistema Hidraulikoa Altzairu Galdutako Argizaria Galdaketa Piezak

Maple makineriak ekipamendu moderno eta sofistikatuetan inbertitzen du Sistema Hidraulikoaren Altzairu Galdutako Argizari Galdaketa Piezen bezeroen eskakizun guztiak betetzeko fidagarritasunari, errepikakortasunari eta malgutasunari dagokionez. Maple makineriak esperientzia zabala du argizaria galtzeko galdaketan eta industria-ziurtagirietan, aldi bakoitzean eguneratzen eta hobetzen diren.

Bidali kontsulta

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy