Deitu iezaguzu

+86-19858305627

E-posta iezaguzu

sales@maple-machinery.com

Itsas Altzairu Galdaketa Piezak Fabrikatzaileak

Gure fabrikak harea galdaketa, trokel itxia, forja irekia, etab. Muturreko diseinua, kalitatezko lehengaiak, errendimendu handia eta prezio lehiakorra dira bezero bakoitzak nahi duena, eta hori ere eskaintzen dizugu. Kalitate handiko, arrazoizko prezioa eta zerbitzu ezin hobea hartzen ditugu.

Produktu beroak

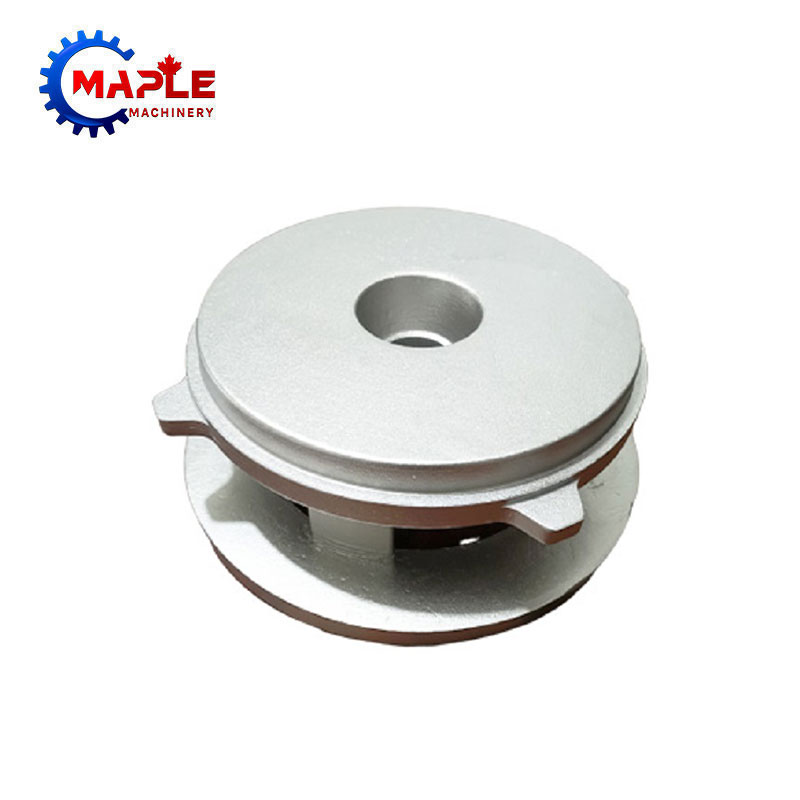

Nekazaritzako Makineria Altzairuzko Zehaztasun Galdaketa Piezak

Zehaztasun-galdaketa tamaina zehatzeko galdaketa lortzeko prozesurako termino orokorra da. Hondar-galdaketa-prozesu tradizionalarekin alderatuta, doitasun-galdaketak galdaketa-tamaina zehatzagoa eta gainazaleko akabera hobea lor ditzake. Maple makineriak esperientzia aberatsa du Nekazaritza Makineriaren piezetan. Nekazaritza-makineria Altzairuzko Galdaketa-Piezak, bereziki. astigarrak makineria altzairuzko zehaztasun galdaketa piezetan espezializatuta dago eta gure bezeroen aitortza eta konfiantza lortu du.Elikagaien Prozesatzeko Makina Altzairuzko Zehaztasun Galdaketa Piezak

Elikagaien Prozesatzeko Makina Altzairuzko Zehaztasun Galdaketa Piezen alorreko fabrikatzaile eta hornitzaile liderra gara. Gure produktu sorta industriako hainbat estandarrekin kalitatea egiaztatuta dago. 15 urte baino gehiagoko esperientzia dugu elikagaiak prozesatzeko industriarako piezak pertsonalizatzen. Ardatz, transmisio, transmisio eta osagai sorta zabala dugu. Talentu handiko hainbat profesional izendatu ditugu. Gure adituak bezeroaren eskakizunak ulertzen saiatzen dira.Balbula Steel Investment Casting Piezas

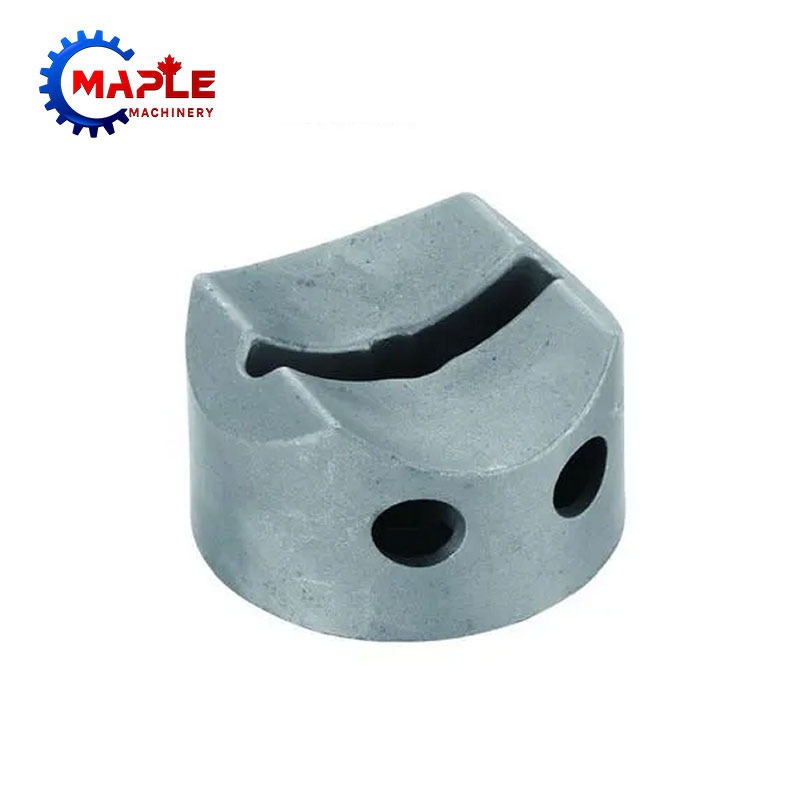

Astigarrak makinetan, Valve Steel Investment Casting Piezen galdaketa-esperientzia zabala dugu, gure bezeroei inbertsio galdaketa prozesutik kalitate handiko galdaketak lortzeko aukera ematen die kostu ekonomiko batekin. Urte askotako esperientzia duen talde tekniko bikaina dugu inbertsio galdaketa diseinu onena eskaintzeko. Behar den edozein laguntza (tolerantzia berrikuspen soiletatik hasi eta aldi berean ingeniaritza osoa) eskuragarri dago gure fundizio-gunean. Valve Steel Investment Casting Parts, astigarrak makinak onena eman diezazuke.Marine Steel Investment Casting Piezas

Maple makineriak galdaketa ekipamendu profesionala eta esperientzia aberatsa du altzairuzko inbertsio galdaketan eta prozesatzen. Aldi berean, Marine Steel Investment Casting Parts ondo egiteko gure modu bereziak ditugu. Inbertsio-galdaketa aukeratzen da inbertsio-galdaketak bigarren mailako prozesamenduaren beharra hein handi batean ezabatzen duelako eta bezeroei kostuak aurrezten eta ekoizpen-denbora laburtzen laguntzen dielako.Eraikuntzako Makineria Altzairuzko Inbertsio Galdaketa Piezak

Maple Machinery galdaketan eta mekanizazioan espezializatutako lantegi moderno bat da, eta eraikuntzako makineria altzairuzko inbertsio-galdaketa-piezen izen fidagarria da. Talentu bikainak dituen taldea gara eta bezeroaren beharrei erantzuteko teknologien erritmoa mantentzen sinesten dugu. Gure fundizio eta makina denda guztiek ISO9001:2015 ziurtagiria gainditu dute. Abantaila geografikoa ematen diguna Ningbo-ren kokapen estrategikoa da, portu-hiri gisa, esportazio-negozioa hobetzen duena.Industria astuneko burdina harikorra galdaketarako piezak

Ningbo-n (Txina) kokatua, portutik hurbil, bere ekoizpen planta du, baita bezeroei kalitatearekin eta azken teknologiarekin lan egiteko irtenbideak eskaintzera dedikatzen den ingeniaritza-talde bat ere. Mundu osoari balio du. Gure espezializazioari, gure makineria modernoari eta kalitate handiko produkzio-teknologiari esker, ekoizpen-faseak kalitate handiko industria astuneko burdinazko galdaketa-piezen kantitate egokia eskaintzen du.

Bidali kontsulta

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy