Deitu iezaguzu

+86-19858305627

E-posta iezaguzu

sales@maple-machinery.com

Burdinurtu ingurumena birziklatzea Fabrikatzaileak

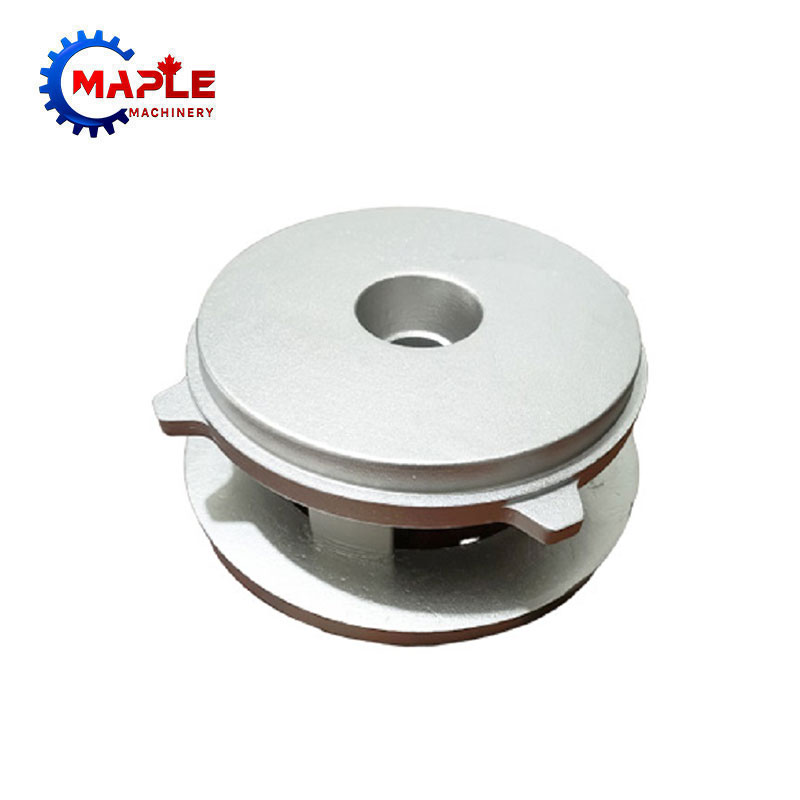

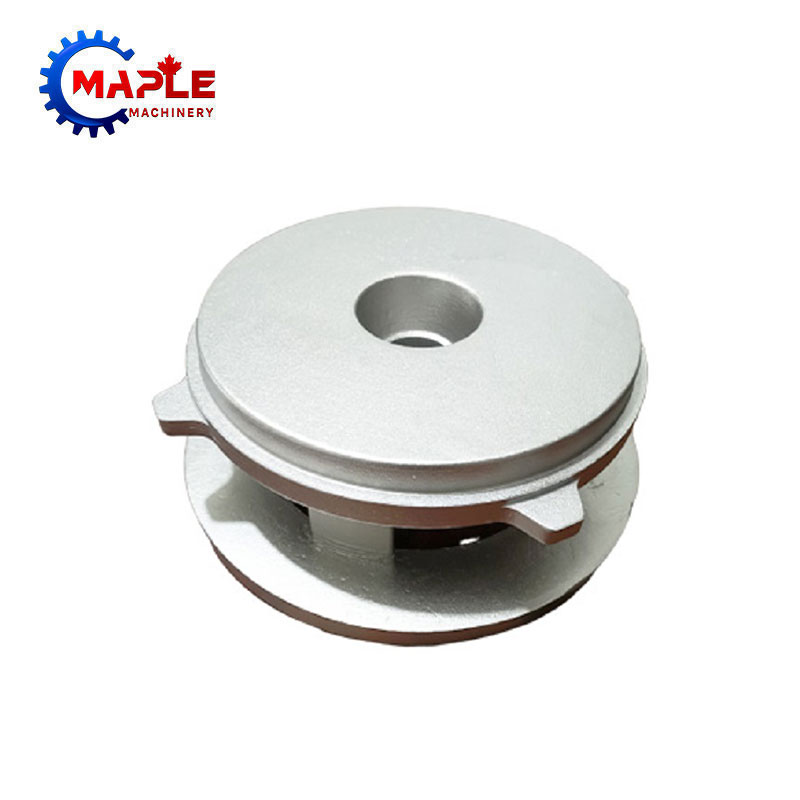

Gure fabrikak harea galdaketa, trokel itxia, forja irekia, etab. Muturreko diseinua, kalitatezko lehengaiak, errendimendu handia eta prezio lehiakorra dira bezero bakoitzak nahi duena, eta hori ere eskaintzen dizugu. Kalitate handiko, arrazoizko prezioa eta zerbitzu ezin hobea hartzen ditugu.

Produktu beroak

Itsas Altzairu Galdutako Argizaria Galdaketa Piezak

Maple makineriaren azpiegitura azpi-zatietan banatzen da, hala nola, fabrikazioa, Kalitate-probak, Salmentak eta Marketina, etab., negozio prozesu leunak bermatzeko. Gure produkzio-unitateak azken ekipamenduz eta teknologia modernoz hornituta daude produkzio prozesu leun bat aurrera eramateko. Gure taldeko langile trebeak eta eskarmentudunak instalatutako ekipamendu eta makineria ezagutzen ditu, eta kalitate oneneko itsas altzairuzko argizaria galdatzeko piezak fabrikatzeko aukera ematen digu.Sistema Hidraulikoa Burdina Harikorra Galdaketa-Piezak

Maple makineria atzerriko bazkide fidagarria da Sistema Hidraulikoko Burdina Harikozko Galdaketa Piezenetarako. Gure produktuak oso erabiliak dira automobilgintza, kimika, eraikuntza, meatzaritza eta beste industria batzuetan. Gure indarra zerbitzu integrala da - galdaketa espezializatuen ekoizpena eskaintzen dugu, baita mekanizazioa eta tratamendu termikoa ere, eta horrela eskaerak gauzatzeko denbora asko murrizten dugu.Petrolioaren eta gasaren industria Burdina grisa galdaketarako piezak

Grey Iron Casting-eko ingeniari, teknikari, foruzain, maketa-mekanikari eta produkzioan modelo-eraikitzaileetatik hasi eta industria mekaniko eta elektronikoko teknikarietara edo industria-kudeaketako laguntzaileetaraino mantentze-lanetan, egunero egiten dute ahalik eta onena gure Oil & Gas Industry bezeroak kalitate handiko galdaketarekin. Aholkularitza eta eskaerak prozesatzeko, petrolioaren eta gasaren industriako burdinazko galdaketako piezen lanak prestatzeko eta ekoizteko, prozesatzeko eta garraiatzeko sakonera arte, talde gisa, helburu komun bat jarraitzen dugu: burdin grisezko galdaketako pieza konplexuak eta kalitate handikoak ekoiztea.Itsas altzairuzko zehaztasun-galdaketako piezak

Maple Machinery-k galdaketa-ekipo profesionala eta esperientzia aberatsa ditu Marine Steel Precision Casting Piezen. Eta kokapen bikaina portutik gertu. Itsasontzietarako altzairu galdaketak egiteko gure modu berezia dugu. Lagundu bezeroei kostuak aurrezten eta ekoizpen denbora laburtzen. Ekoizpenaren kalitatea hobetzea.Meatzaritza Industria Altzairu Galdutako Argizaria Galdaketa Piezak

Gure Meatze Industriako Altzairu Galdutako Argizaria Galdaketa Piezak oso erabiliak dira meatzaritza eta mineralak prozesatzeko eremuetan. Kalitate altu eta egonkorrarekin, 20 urte baino gehiagoko esperientzia profesionala dugu. Galdaketa teknologia aurreratua dugu, meatze-makineria bezeroen leherketa-froga eskakizun teknikoak bete ditzakeena. Diseinuaren, simulazioaren, galdaketaren eta mekanizazioaren alderdietatik irtenbideak eman behar badituzu eta zure Meatzaritza Industriako Altzairu Galdutako Argizari Galdaketa Piezen ezarpenerako iradokizun eraginkor batzuk eman behar badituzu, pozik gaude zure galdaketa-aditu bihurtzea.Eraikuntzako Makineria Burdina Harea Galdaketa Piezak

Maple Machinery kalitate handiko burdinurtu eta altzairu galdaketaren fabrikatzaile berritzailea da, Ningbo-n (Txina) egoitza nagusia. Mundu mailan aitortzen den eraikuntzako makinen hornitzaile liderra da, zehaztasun handiko eta konplexutasun handiko burdinazko harea galdaketako piezen. Gure taldeak proiektu bakoitzaren kalitatearekin konprometituta dago, bezeroen gogobetetasun handiena bermatzeko.

Bidali kontsulta

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy