Deitu iezaguzu

+86-19858305627

E-posta iezaguzu

sales@maple-machinery.com

Nekazaritzako Makineria Altzairuzko Inbertsio Galdaketa Piezak Fabrikatzaileak

Gure fabrikak harea galdaketa, trokel itxia, forja irekia, etab. Muturreko diseinua, kalitatezko lehengaiak, errendimendu handia eta prezio lehiakorra dira bezero bakoitzak nahi duena, eta hori ere eskaintzen dizugu. Kalitate handiko, arrazoizko prezioa eta zerbitzu ezin hobea hartzen ditugu.

Produktu beroak

Ingeniaritza Zibileko altzairu herdoilgaitzezko forja-piezak

Altzairu herdoilgaitzezko motako habeek eraikuntza, ingeniaritza, eraikuntza eta egitura altzairuaren mundu zabalean duten garrantzia. Altzairu herdoilgaitzezko habe forjatuak Ingeniaritza Zibilaren zati garrantzitsu bat izan dira 15 urte baino gehiagoz. Altzairu herdoilgaitzezko piezen hornitzaile gisa, Maple makinak gure taldeak zuretzat egokitutako Ingeniaritza Zibileko altzairu herdoilgaitzezko forja-pieza ugari ekoizten ditu. Zure piezen fabrikatzaile fidagarri bat garaPetrolioaren eta Gasaren Industria Altzairuaren Inbertsioa Galdaketa-Piezak

Maple-ren galdaketa petrolioaren eta gasaren industrian 15 urte baino gehiago daramatza, eta ekipamenduen fabrikatzaileekin eta hornikuntza-katearekin epe luzeko lankidetzaren ostean, esperientzia zabala dugu. Bezeroei kalitate handiko petrolio eta gas industria altzairuzko galdaketarako piezak eskaintzen dizkiegu, arreta handia jartzen diegu korrosioarekiko erresistentziari eta piezen iraunkortasunari, eta behar den entrega-epea ere zorrotz betetzen dugu. Nekazaritzak bezala, industria honek ere bere aldizkakotasun potentziala du, beraz, pieza guztiak garaiz entregatu behar diraBirziklapen industria Altzairu herdoilgaitzezko forja-piezak

Mundu jasangarriago baten bila, birziklapenaren industria altzairu herdoilgaitzezko forja-piezak aliatu baliotsua dela frogatu du arkitekto, ingeniari eta kontratistarentzat, proiektuetarako ez ezik, gizarte osoarentzat onura anitzekin. Industria altzairu herdoilgaitzezko forja-pieza birziklatuak erabiltzearen abantailen artean, proiektuaren kostuak murriztea eta estetika, fidagarritasuna eta aurreikuspen handiagoak daude. Iraunkortasunaren ikuspuntutik, altzairu herdoilgaitza material teknologia aurreratuekin konbinatuz altuera berrietara iritsi daiteke.Sistema Hidraulikoa Burdina Grisa Galdaketa Piezak

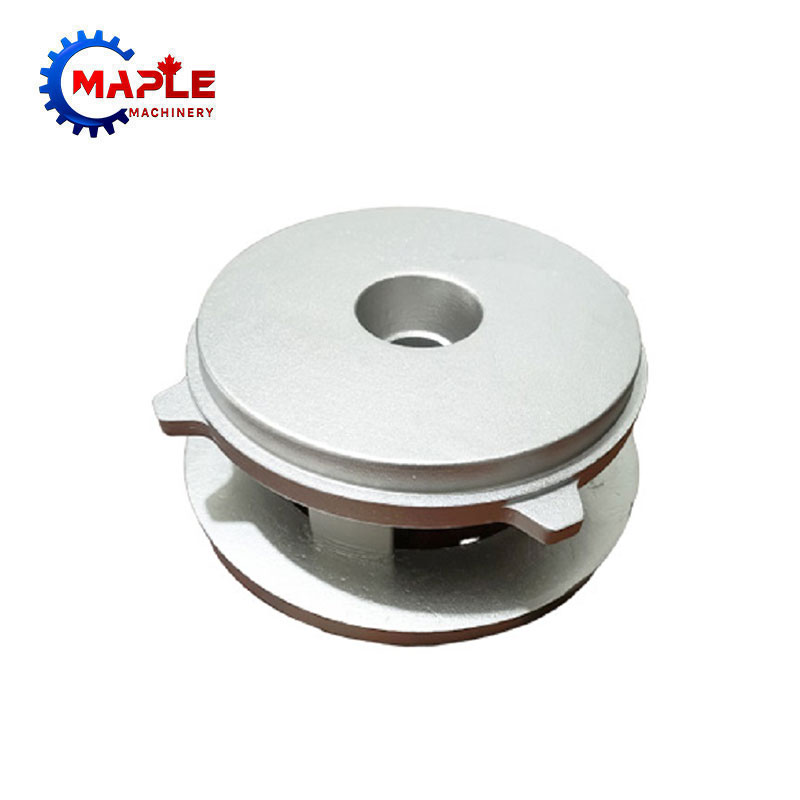

Burdin harikorra eta burdin grisa galdaketa gara eta Ningbon, Txinan, garatutako osagaien galdaketa produktuen hornitzailea gara. Izan ere, azken 15 urteotan, galdaketa teknologia hazi eta aurreratu dugu. Onak gara Sistema Hidraulikoaren Burdina Grisa Galdaketa Pieza fabrikatzen. Baina beste produkzio sektore batzuei ere zerbitzatzen diegu: Itsas motorrak, makina-erreminta, energia, meatzaritza eta automatizazioa.Industria Burdinazko Harea Galdaketa Piezak

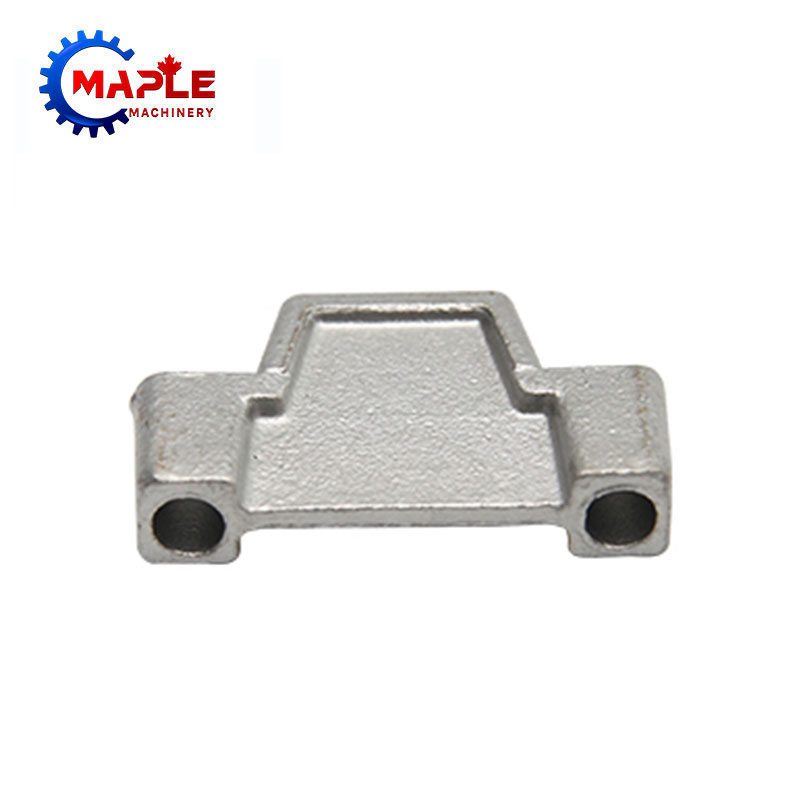

Maple Makineria Industria Burdinazko Harea Galdaketa Piezen fabrikatzailea da, galdaketa mota ezberdinen ekoizpenean espezializatua. Kide-enpresa bakoitzak bere ezagutza eta ekoizpen-teknologia espezifikoak ditu. Burdinola guztiek beren jarduera independenteak dituzte. Konpainiak neurrira egindako Iron Sand Casting Piezas egiten ditu mundu mailako bezeroentzatBalbula Altzairu Galdaketa Pieza

Maple makineriaren kalitate-kontrola oso zorrotza da. Valve Steel Casting Parts urtero kantitate handietan ekoizten dugun produktua da, baina Maple makineria ez da inoiz altxatzen. Tailer guztietan kalitate- eta segurtasun-zerrenda sistema erabiltzen da. Aldian-aldian egiaztatu probatzaile eta neurketa tresna guztien fidagarritasuna eta langileen gaitasunak. Beharrezkoa da produkzio-plana kontrolatzea eta proba ez-suntsitzaileak kalitate-kontrolerako bitarteko nagusiak izatea.

Bidali kontsulta

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy