Deitu iezaguzu

+86-19858305627

E-posta iezaguzu

sales@maple-machinery.com

Nekazaritza-makineria Altzairu herdoilgaitzezko galdaketa-piezak Fabrikatzaileak

Gure fabrikak harea galdaketa, trokel itxia, forja irekia, etab. Muturreko diseinua, kalitatezko lehengaiak, errendimendu handia eta prezio lehiakorra dira bezero bakoitzak nahi duena, eta hori ere eskaintzen dizugu. Kalitate handiko, arrazoizko prezioa eta zerbitzu ezin hobea hartzen ditugu.

Produktu beroak

Sistema Hidraulikoa Burdina Harea Galdaketa Piezak

Maple Leaf Machinery Co., Ltd.-k sistema hidraulikoko burdinazko harea galdaketarako piezak ekoizten ditu, eta azken 15 urteotan gure talentua hobetzen ari gara. Gure ezagutzak erabiltzen ditugu Sistema Hidraulikoko Burdinazko Harea Galdaketa Piezen praktika eta teknika onenak transmititzeko eta galdaketa prozesuetan azken aurrerapenak hartzeko. Konpainiak hareazko moldeen galdaketan, shell moldeen galdaketan eta argizari galduetan oinarritzen da batez ere, eta etengabe zabaltzen ditu laguntza-instalazioak, teknologiak, ekipamenduak eta zerbitzuak.Elikagaien Prozesatzeko Makina Altzairu herdoilgaitzezko galdaketarako piezak

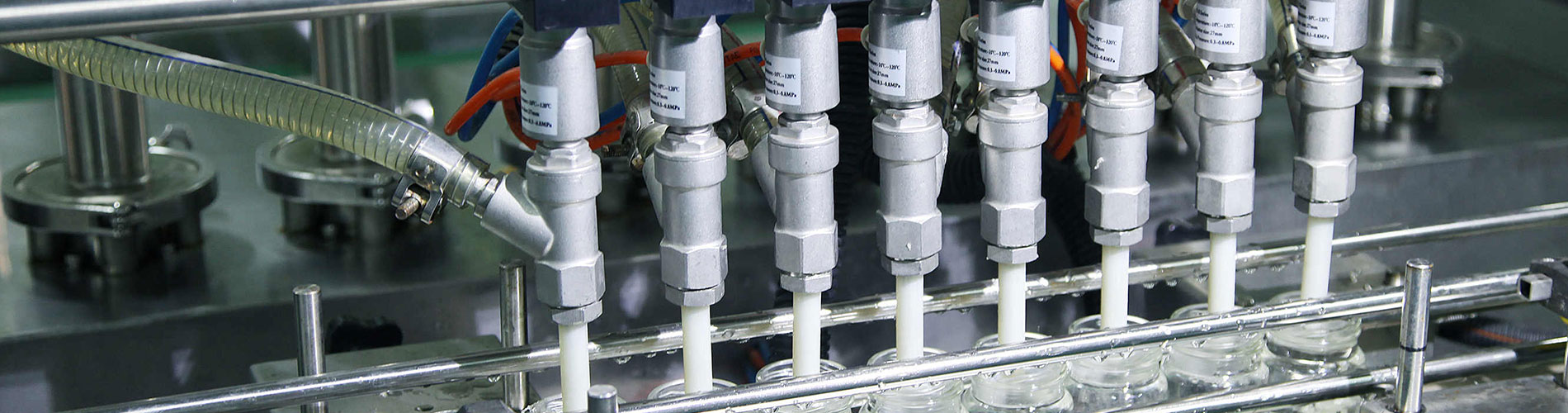

Elikagaien Prozesatzeko Makinarentzat, Maple makineria ingeniariek zure erakundearen luzapen gisa jokatzen dute doitasun galdaketaren garapenean. Gauzak "teknikoki hobeak, desberdinak, merkeagoak edo/eta sinpleagoak" izan daitezkeen kontuan hartuta, irtenbiderik onena prezio lehiakorrean lortzen dugu. Pozik gaude Galdaketa tekniken ezagutza zurekin partekatzeko Elikagaien Prozesatzeko Makina Altzairu Herdoilgaitzezko Galdaketa Pieza onenak diseinatzeko.Nekazaritzako Makineria Altzairuzko Trokel Itxiak Forjatzeko Piezak

MapleMachinery-k ia 20 urteko esperientzia du nekazaritzako ekipoen industrian. Aleazioak forjatu eta prozesatzen ditugu, karbono altzairua, altzairu aleatua, altzairu herdoilgaitza eta aluminioa barne. Gure forjaren azken erabilerak nekazaritza-makinen zatietatik hasi eta laboreak biltzeko ekipoen osagai nagusietaraino daude. Nekazaritza-ekipoen kostua murrizteko, astigarrak forja-prozesuetako batzuk automatizatu ditu, nekazaritza-makineria altzairuzko trokel itxiak propietate mekaniko koherenteekin fabrikatzeko eta ekoizpen-zikloa asko laburtzeko.Industria astuneko altzairuzko zehaztasun-galdaketako piezak

Maple makineriak produktu eta zerbitzu fidagarrienak ditu. Gainera, hornikuntza koherenteena eta kalitatezko segurtasun onena lortzeko gai gara gure integrazio bertikal bikaina dela eta - meatzaritzatik ekoizpenera zerbitzu osoko irtenbide bat emateko gaitasuna. Hori dela eta, Heavy Industry Steel Precision Casting Parts for Maple makineria izan daitekeen onena izan dadin erabat da.Meatze industria Altzairu herdoilgaitzezko forja-piezak

Maple makinak altzairu herdoilgaitzezko forjatuak ekoizten ditu. Bezeroek emandako marrazkien edo laginen arabera garatzen eta ekoizten ditugu Meatze Industria Altzairu herdoilgaitzezko forja-piezak. Lehenik eta behin, prozesu bakoitzaren ondoren dagokion egiaztapena egiten dugu. Azken produktuari dagokionez, %100eko ikuskapen osoa egingo dugu bezeroen eskakizunen eta nazioarteko estandarren arabera. Kalitate bikainarekin, kalitate handiko zerbitzuarekin eta prezio lehiakorrarekin, Meatze Industriako bezeroek konfiantza dute.Off Highway Industria altzairu galdaketa piezak

MapleMachinery-k 20 urte baino gehiagoko ezagutza du erresistentzia handiko aleazioetan, manganeso-aleazioetan eta kastruioan. Gure esperientziadun ingeniaritza eta salmenta sailek beren espezializazioa erabiltzen dute Erresistentzia handiko Off Highway Industry Steel Casting Parts eskaintzeko, edozein trenbide bezeroren eskakizunak asetzeko. Gure piezak kalitate handiko lehengaiekin diseinatuta daude, trenbideko bezeroei trakzio-erresistentzia, korrosioarekiko erresistentzia eta errendimendu onena duten piezak eskaintzen dizkiegula ziurtatzeko. MapleMachinery-k pieza zaurgarrietarako aleazio pertsonalizatuak eta jabedunak ere garatu ditu, eta mikroegituraren eta beste propietate fisikoen eskakizun zehatzak betetzeko gaitasuna dugu.

Bidali kontsulta

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy