Produktuak

- View as

Meatze industria Altzairu herdoilgaitzezko forja-piezak

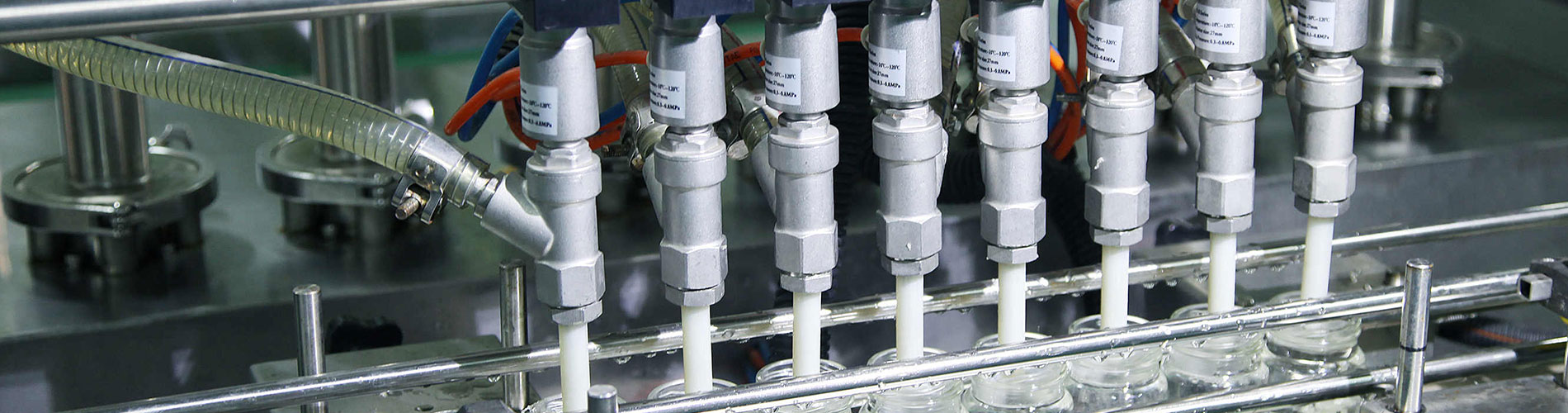

Maple makinak altzairu herdoilgaitzezko forjatuak ekoizten ditu. Bezeroek emandako marrazkien edo laginen arabera garatzen eta ekoizten ditugu Meatze Industria Altzairu herdoilgaitzezko forja-piezak. Lehenik eta behin, prozesu bakoitzaren ondoren dagokion egiaztapena egiten dugu. Azken produktuari dagokionez, %100eko ikuskapen osoa egingo dugu bezeroen eskakizunen eta nazioarteko estandarren arabera. Kalitate bikainarekin, kalitate handiko zerbitzuarekin eta prezio lehiakorrarekin, Meatze Industriako bezeroek konfiantza dute.

Irakurri gehiagoBidali kontsultaSistema hidraulikoa altzairuzko trokel itxia forjatzeko piezak

Maple makineria etengabeko hobekuntza eta ahaleginak, ekipamendua masa ekoizpenerako prest egon da. Sistema hidraulikoaren altzairuzko trokel itxiak forjatzeko piezak bezeroaren jarraipenaren eta ikerketaren bidez, funtzioa, kalitatearen egonkortasuna, kontrol mekanikoa eta ekipoen kontrol-zehaztasuna aho batez baieztatu ditu Hydraulic System Steel bezeroak. Produktibitatearen garapenarekin eta zientziaren eta teknologiaren aurrerapenarekin, gure makineria eraginkorrak gero eta paper garrantzitsuagoa betetzen ari da fabrikazio enpresetan eraginkortasuna hobetzeko eta produktuaren kalitatea hobetzeko.

Irakurri gehiagoBidali kontsultaIngeniaritza Zibileko altzairuzko trokel itxiak forjatzeko piezak

20 urte baino gehiagoz, Maple Machinery Co., Ltd., Ningbo-n (Txina) kokatua, trokel itxien forjatzaileen fabrikatzaile profesionala da, bezeroei kalitate handiko Ingeniaritza Zibileko altzairuzko forja-piezak eskaintzeko espezializatua. Horrez gain, produktu bukatuetarako balio erantsiko beste zerbitzu batzuk ere eman ditzakegu. Hori dela eta, pieza forjatuak eta mekanizatuak behar badituzu, jar zaitez gurekin harremanetan!

Irakurri gehiagoBidali kontsultaIngeniaritza Zibileko altzairuzko forjarako piezak

Maple Machinery Co., LTD., Ningbo-n (Txina) kokatutako Forja-Piezen fabrikatzailea da, portu kokapen bikaina eta entrega erosoa dituena, eta kalitate handiko Ingeniaritza Zibileko Altzairuzko forja-piezak eskaintzen ditu Ingeniaritza Zibileko bezero globalei. Eta emaitza onekin, balio erantsiko beste zerbitzu batzuk ere eman ditzakegu amaitutako produktuarentzat.

Irakurri gehiagoBidali kontsultaSistema hidraulikoa Altzairu herdoilgaitzezko galdaketako piezak

Maple makineriaren sistema hidraulikoa altzairu herdoilgaitzezko galdaketarako piezak fidagarritasunagatik ezaguna da, baina fidagarritasunean oinarritutako gure lan-etika ez da hor gelditzen. Gure lanaren alderdi guztietan agertzen dela ziurtatu nahi dugu, gure produktuetatik hasi eta bezeroen arretarako eta lankidetzarekin. Harro gaude epe luzerako bezeroekiko harremanak sortzeaz.

Irakurri gehiagoBidali kontsultaItsas altzairu herdoilgaitzezko galdaketa piezak

Maple machinery is a professional manufacturer located in Ningbo, China. More than 15 years of experience in the steel industry. Our products mainly include Marine Stainless Steel Casting Parts. Our products have been exported to many countries in Europe and America. We have a wealth of foundry experience, but also a number of stable Marine industry customers.产品内容 Product Introduction Maple machinery offers a wide range of custom Marine Stainless Steel Casting Parts. Stainless steel is resistant to corrosion and heat, has aesthetic appeal and low life cycle cost, is fully recyclable and has a good strength-to-weight ratio. We offer austenite, ferrite, martensite and biphase grades: we have hot or cold rolled and various surface treatments such as bright annealing. You can count on our experience. 2. Product Parameter (Specification) Item Marine Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Marine Maple machinery has been the most demanding supplier of Marine Stainless Steel Casting Parts for more than 15 years. Our reputation has earned us partners and valued customers who follow the most stringent requirements in terms of microstructure integrity, dimensional tolerances and quality control. Our products meet customers' requirements and standards. 4.Supporting Service for Marine As mentioned above, in order to work in adverse conditions, the performance of the Marine Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Marine Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Marine We have manufactured a wide range of Marine Stainless Steel Casting Parts. The following are typical products: Ground engaging tools: drill bits, carbide tipped tool, forged bucket tooth, auger.... 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.

Irakurri gehiagoBidali kontsulta