Produktuak

- View as

Balbula altzairu itxitako trokelak forjatzeko piezak

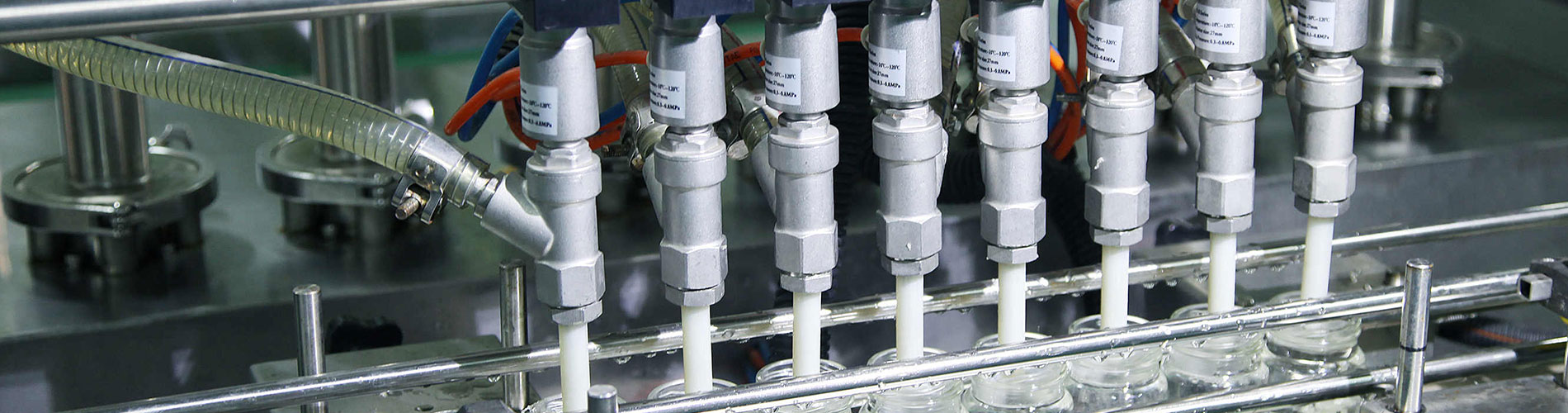

Kalitate handiko Balbula altzairuzko Trokel Itxiak Forjatzeko Piezak eskaintzen ditugu, baita malgutasuna eta erantzukizuna ere Balbula industriaren eskakizun handiak asetzeko eta baita haratago ere. Balbula-Piezak edo beste Trokel Forja-Piezak diren ala ez, astigarrak makinetan fabrikatzen ditugu. Gozatu kalitate eta bezeroari begirako ikuspegi berarekin. Garatu eta ekoitzi ditzagun guztiz altzairu itxiko trokel forjatuak

Irakurri gehiagoBidali kontsultaIndustria astuneko altzairuzko trokel itxiak forjatzeko piezak

Maple makineria Trokel Itxien Forjazioan espezializatuta dago, kalitate handiko Industria Astuneko Altzairuzko Trokel Itxien Forjaketa Piezen fabrikazioan. Gure negozio-esparrua marketina globala da. Gaur egun, konpainiak epe luzerako lankidetza harremanak ezarri ditu etxean eta atzerrian bezero ezagun askorekin. Maple makinen kultura autoesplotaziorako balioa sortzea da. Bere onuradun handienak bere bezeroak dira. Ondorioz, Maple makineria gure bezeroentzako bazkide fidagarria eta dedikatua izan da eta izango da.

Irakurri gehiagoBidali kontsultaItsas altzairuzko forjarako piezak

Metal Forjaketa mota nagusi gisa, Steel Forging altzairua konformatzeko teknologia bat da, tokiko konpresio indarra erabiltzen duena. Forjatzeek aldaketa nabarmenak izan dituzte, prozesu eraginkorragoak, azkarragoak eta iraunkorragoak izateko. Gaur egun, itsas altzairuzko forja-piezak, normalean, forja-prentsa edo mailu tresna elektriko, hidrauliko edo aire konprimituarekin egiten dira. Forjatze beroan pieza urtze-tenperaturaren %75 ingurura berotzea dakar.

Irakurri gehiagoBidali kontsultaElikagaien Prozesatzeko Makina Altzairuzko Forjaketa Piezak

Maple makineriak etengabe inbertitzen du gure pertsonen, prozesuen eta makinen garapenean gure garapen-helburuak lortzeko. Inbertsioak eta berrikuntzak Elikagaien Prozesatzeko Makina Altzairuzko Forjaketa Piezen estandarra bermatu dute. Etengabeko barne garapena eta perfekzioaren bila ari garela, bezeroek aintzat hartu gaituzte.

Irakurri gehiagoBidali kontsultaBalbula altzairuzko forja-piezak

We at Maple machinery guarantee the quality and impeccable service of every Valve Steel Forging parts. We strive for excellence every day, using all of our expertise and tremendous commitment to ensure maximum efficiency. We aim at innovation to create a better future and bravely face every new challenge. Product Introduction The different Forging techniques offered by Maple machiney Forging solutions enable us to forge the different Valve Steel Forging parts of valves all of which are designed to the customer's requirements and are also checked and verified in a simulator before forging. The resources and skills of our staff enable us to forge any type of material that is processed on our heat treatment equipment and completed after conducting final destructive and non-destructive tests. They are provided on delivery terms agreed with the customer and include all required documents and certificates. 2. Product Parameter (Specification) Item Valve Steel Forging parts Roughness Ra 1.6 Tolerance ±0.01mm Material Alloy Steel Certification ISO 9001:2015 Weight 0.01-60KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Closed Die Forging Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Valve Our Valve Steel Forging parts have a worldwide reputation for their high quality and reliability. With our state-of-the-art testing laboratories and highly qualified workforce, we combine the highest standards of technology, quality and productivity. Accurate delivery time, fast service, we get the customer's praise. 4.Supporting Service for Valve parts As mentioned above, in order to work in adverse conditions, the performance of the Valve Valve Steel Forging parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Agricultural Machinery We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Valve Steel Forging parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Valve We have manufactured a wide range of Valve Steel Forging parts. The following are typical products: Valve joint, Ball valve body, Gate valve body, Choke valve body,Beer valve body,Purification water brass,Hybrid valve, .... 6. Why Closed Die Forging Compared with casting, forging has its special advantages: 1. In the case of the same material, the mechanical properties of forgings are better than those of castings. 2. The forgings strength is higher and the fatigue resistance is stronger. 3. The forgings has better compactness. 4. There are no internal defects and surface defects. 5. Fast production speed, high efficiency, suitable for mass production of products. 6. The product quality is stable.

Irakurri gehiagoBidali kontsultaIndustria astuneko altzairuzko forjarako piezak

Maple makineria azkar hazten ari den forja-produktuen hornitzailea da Txinan, gaur egungo forja-produktuen erronkei erantzutera bideratuta. Lorpen handia izan da bere sorreratik eta Industria Astunerako altzairu-kalifikazio ezberdinen forja-hornitzaile nagusietako bat da. Maple makineria bezero entzutetsuek eta proba-agentziek aitortzen dute bere kalitatezko industria astuneko altzairuzko forja-piezengatik. Gure konpainiak teknologia aurreratuenera bideratu du beti forja-produktu hobeak eskaintzeko urtez urte.

Irakurri gehiagoBidali kontsulta